Spotlight Service Series – High Velocity Flushing

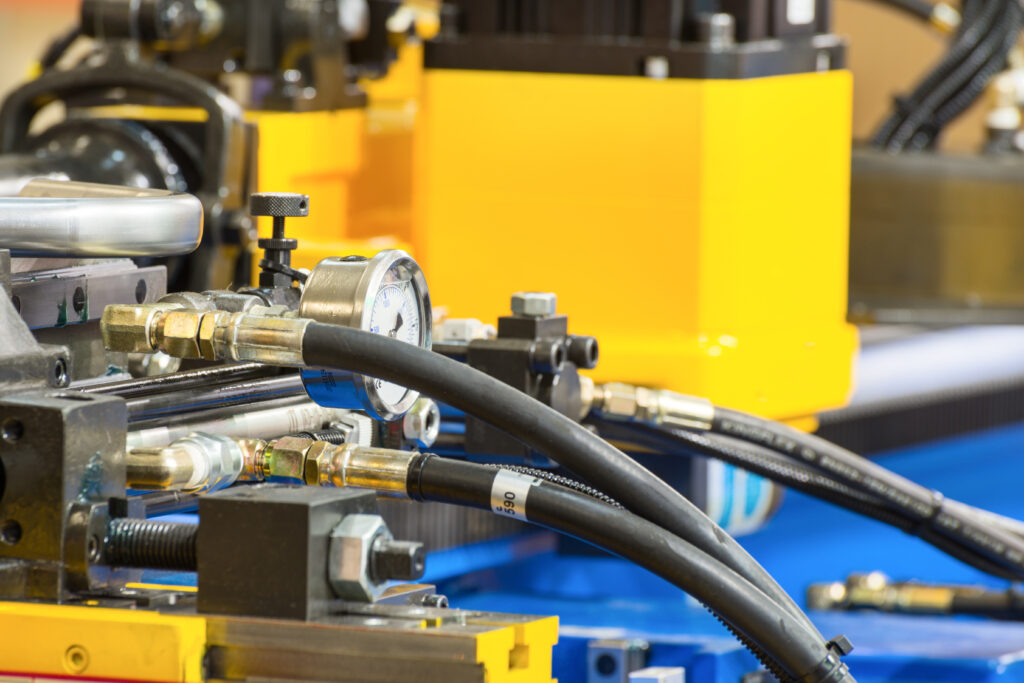

High Velocity Flushing (HVOF) is best practice to remove harmful contaminants from the internal surfaces of lube piping. From rainwater to dust pick-up, these contaminants can and will enter your piping and tubing systems.

Our flushing services use circulation heaters to heat liquid at a high temperature. By doing so, this loosens and forces harmful contaminants out at high speeds which are then “flushed” through your piping and machinery.

Most commonly, dirt contamination is an issue causing premature pump and critical component failure. Buildup and corrosion can occur resulting in your equipment working harder, heating at higher temperatures, and causing premature wear and tear.

Performing high velocity flushing on your hydraulic and lube oil systems by one of our trained technicians can improve your equipment’s reliability and reduce unnecessary downtime. Flushing is an essential maintenance process that can be performed both before equipment start-up and as part of routine maintenance.

Your equipment and its circulating system will be inspected by our reliability team to determine how clean they are. Based on the pipe’s specifications and needs, a comprehensive oil flush plan will be developed.

As part of the flushing plan, any contaminants that may compromise the equipment and its performance will be effectively removed. Once completed, the cleanliness requirement will be verified, and a summary report of the oil flush will be provided by our reliability team.

Benefits of High Velocity Flushing:

- Decreased downtime, increased revenue

- Improved equipment reliability

- Decreased maintenance costs

- Meet or exceed iso cleanliness requirements

Is your equipment in need of our flushing services? Give us a call at (337) 602-6781 or shoot us an email at services@breauxpetroleum.com.