How Healthy is Your Oil?

Reliability operators know that monitoring the condition of oil is essential for preventing unnecessary downtime.

Like bloodwork taken for a routine checkup, oil analysis is a firsthand look at the vital fluids running through the key components of rotating equipment. It can aid in identifying when and where foreign contaminants are being introduced into your system and can also pinpoint mechanical wear issues before catastrophic failures occur.

The results of an oil analysis should indicate if your oil is up to the task and performing as it should. These days, industrial equipment is working harder, for longer, under increasingly demanding conditions, which creates significant risk for your bottom line. As a result, protecting your expensive assets has never been so important, which is where a robust maintenance strategy – and oil condition monitoring – comes in.

With oil condition monitoring, you can monitor, investigate, and analyze your fluid health. Any changing characteristics found in your monitoring reports will indicate where your equipment maintenance resources are best spent. Changing your oil too early can be a waste of time, resource, and money, while changing too late risks damaging your equipment and raising the likelihood of failure.

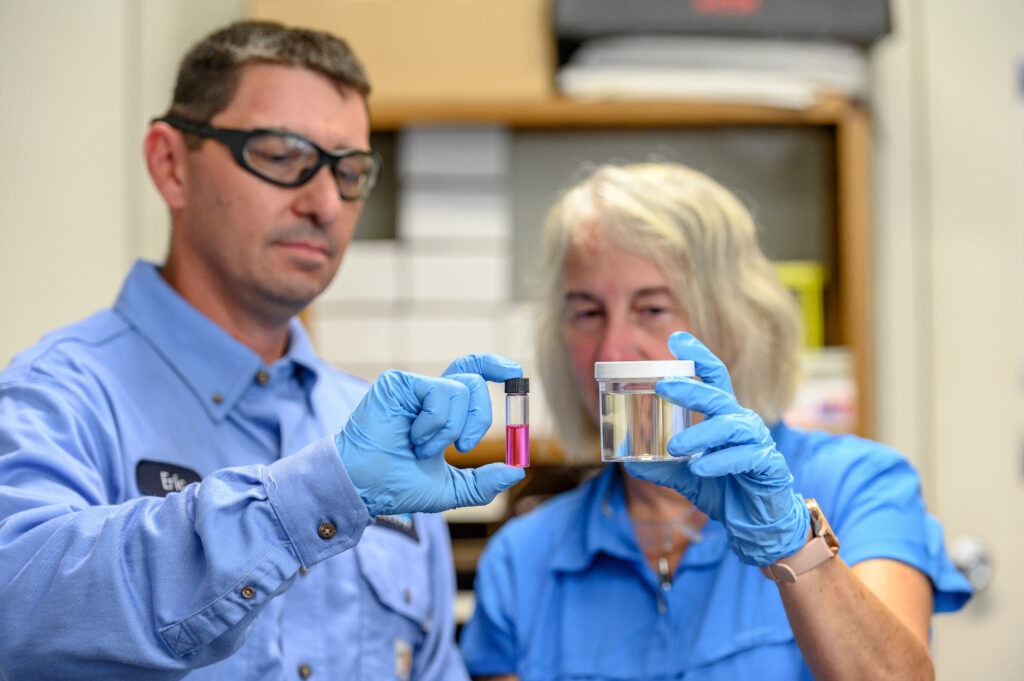

At Breaux Petroleum, we offer condition monitoring services to keep an eye on the viscosity, cleanliness, varnish potential, and overall fluid health of your oil. With this information, timely insights and recommendations can be provided to create the best path forward.

Performing oil monitoring at consistent intervals is key to your return on investment in both your lubricants and equipment. Our experienced service technicians can find the causal factors affecting changes in your oil sample reports, while plotting and tracking trends, to help form an effective maintenance strategy. With visibility into the inner workings of your oil performance, you’re able to make better-informed maintenance – and business – decisions.

The beginning of every solution is a conversation. Learn more about our condition monitoring services and talk to one of our experts today to take the next step in improving your operation.