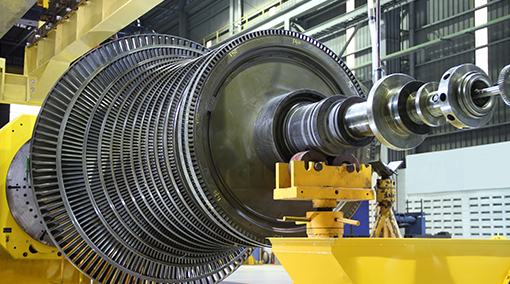

Are You Doing Enough for Your Turbines?

By Myles Pryor

Turbines are a critical component of rotating assets, and their lubrication health plays a large role in ensuring machine reliability. Oftentimes, a key cause of turbine failure can be linked to varnishing.

Varnish within lube oils is often caused by thermal degradation, oxidation, and/or contamination. Varnishing can lead to several operational issues including filter plugging, and more importantly, failure of bearings and other critical components due to excessive wear.

Early signs and even late stages of varnishing can go unnoticed in basic or routine elemental analysis, such as Total Base Number (TBN) and Total Acid Number (TAN) oil sampling. One relatively simple test that can determine impending varnish problems is Membrane Patch Colorimetry.

Membrane Patch Colorimetry is the only test that can effectively identify the onset of varnish within a turbine oil. Adding Membrane Patch Colorimetry to your monthly or quarterly sampling can allow your reliability team to act early before the snowball effect of varnishing continues.

If testing discovers that your varnish potential is 30 or higher and is the only issue flagging in your sample, a simple filtration unit can be installed in line with your system to extend the life of your oil and most importantly, your equipment.

Breaux Petroleum Products can assist you with turbine oil testing as well as customized solutions for any uncovered issues. Contact us today for more information on turbine oil testing and other services that can enhance the life and reliability of your machinery.